- Oil-free Air Compressor

- Oil-free Air Blowers

- Scroll Air Compressor

- Air Compressor

- Stationary Air Compressor

- KAISHAN LG oil-lubricated rotary Screw Compressor

- KAISHAN LG two-stage rotary Screw Air Compressor

- KAISHAN LG Water-cooled Screw Air Compressor

- Kaishan KSZJ diesel Air Compressor

- Boreas Screw Compressor

- KAITAIN JN Energy-efficient Screw Air Compressor

- KAITAIN JN Two-stage Compression Screw Air Compressor

- Kaitain JN Integrated Screw Air Compressor

- JN High Pressure Screw Air Compressor

- Kaitain PM Variable Frequency Screw Air Compressor

- Kaitain KAITEC 0.3Mpa Low Pressure Screw Air Compressor

- Kaitain 0.5Mpa Low Pressure Screw Air Compressor

- KAITEC KHE Screw Air Compressor

- KAITEC KHE two-stage rotary screw air compressor

- KAITEC 0.15Mpa-0.2Mpa Low Pressure Screw Air Compressor

- KAITEC 0.3Mpa Low Pressure Screw Air Compressor

- Kaitec 0.5Mpa Low Pressure Screw Air Compressor

- KAITEC KHE High Pressure Screw Air Compressor

- KAISHAN VJ Variable Frequency Screw Compressor

- Portable Air Compressor

- KAISHAN BKCY diesel Screw Compressor

- Kaishan KSCY diesel mobile Air Compressor

- KAISHAN LGCY Diesel Portable Screw Air Compressor

- KAISHAN LG Electrical Portable Screw Air Compressor

- KAISHAN LG High Pressure Diesel portable Screw Air Compressor

- KAISHAN ML Explosion-proof Screw Air Compressor

- KAISHAN LGJY Mining Screw Air Compressor

- KAISHAN LGN Screw Air Compressor

- KAISHAN LGYT Mining Screw Air Compressor

- Piston Air Compressor

- KAISHAN KA Medium Pressure Industrial Air Compressor

- KAISHAN KB High Pressure Industrial Air Compressor

- KAISHAN KJ Low Pressure Industrial Piston Air Compressor

- KAISHAN KS Low Pressure Industrial Piston Air Compressor

- KAISHAN Mining industry Piston Air Compressor

- Kaitec Screw Vacuum Pump

- High-speed Single-stage Centrifugal Blower

- Industrial Refrigeration Heat Pump Applied Screw Compressor

- Centrifugal Air Compressor

- Centrifugal Steam Compressor

- Centrifugal Refrigerating Compressor

- Gas Air Compressor

- ORC Screw Expansion Power Station

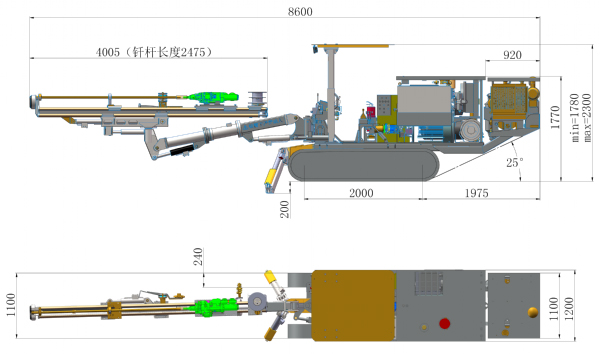

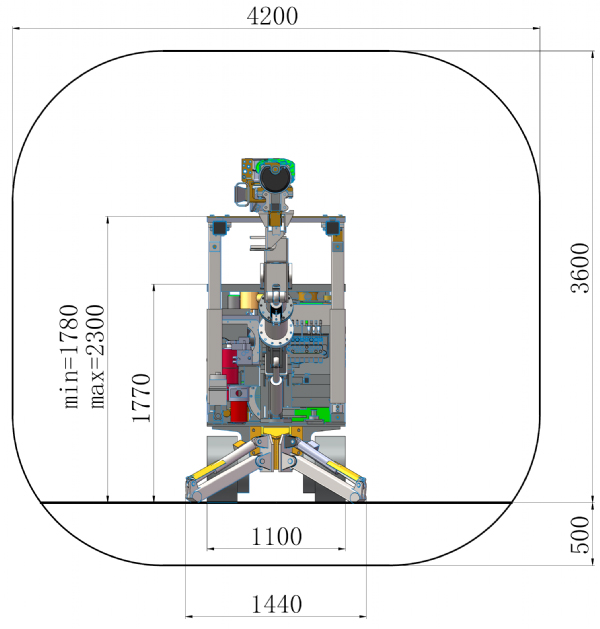

KJ210 Underground Mining Drill Rigs and Tunneling Jumbo is applicable to tunneling of hard rock mines in small and medium section roadways, with a roadway section of 15m2(width 4.2m× height 3.6m), satisfying any angle and location required by construction in this roadway.

The jumbo is equipped with a support frame, which stabilizes the jumbo through its front leg when the jumbo works, ensuring stable and reliable operation.

The hydraulic system of the jumbo has a perfect protective device. After the rock drilling, the rock driller will stop work automatically; a protective device of anti-clamping bit; the protective device of warning of such failures as low oil level, too high oil temperature, an d filter clogging.

Various control buttons and control valves are installed together for easy operation.

The drill arm of the rock driller can rise and fall steadily, with flexible rotation and accurate borehole positioning.

The entire jumbo is arranged reasonably, and all its repair and maintenance parts have been protected well, and its repair and maintenance are easy.

The high-frequency percussion rock driller uses the cascaded piston to optimize the efficiency of shock wave transmission, raise the drilling speed, reduce clamping bit consumption and enhance the soundness of device.

A series of automatic functions can help the driver to concentrate their attention to safe, rapid and accurate drilling.

The reliable universal big arm has the best shape of section coverage, boosting the 360° overturn of the beam for rapid and convenient borehole positioning.

A diesel engine power station can be added to transfer the jumbo conveniently to another site. Modular design is applied for the diesel engine power station to make assembly and disassembly convenient.

Technical Parameters of KJ210 Underground Mining Drill Rigs and Tunneling Jumbo

Dimensions versus Weight |

Drilling system |

||

Length |

8600mm |

Rock drilling |

HC50/R38 |

Width |

1200mm |

Impact power |

13kW |

Height |

1780mm |

Impact pressure |

130bar |

Weight |

6200 kg |

Maximum rotation pressure |

150bar |

Travelling speed, level |

2km/h |

Frequency |

62Hz |

Climbing capacity |

20° |

Torque |

325Nm |

Security |

Aperture |

Φ38-76mm |

|

Noise level |

<100dB(A) |

Rolling of the propelling beam |

360° |

Lifting safety ceiling |

It conforms to the requirement to prevent rolling and falling rock. |

Compensative travel of propelling beam |

1200mm |

Wind and water route system |

Extension of drill boom |

2100mm |

|

Air Compressor |

1×JN5 |

BoomModel |

K10 |

Capacity |

0.5m3/min |

|

|

Pressure |

8bar |

Electric Hydraulic pump station |

|

Lubricating device of drill rod tail |

Forced feed lubricating can |

Electric motor |

45kW Three phase |

Gas consumption for lubrication |

0.3 m3/min |

Impact- propelling- drill boom |

Variable axial piston pump |

Oil consumption for lubrication |

180-250g/h |

Turn around |

Gear pumps |

Pump |

1×CR3 |

Filter precision |

10μ |

Power |

1.5kW |

Hydraulic oil tank |

240L |

Pump Capacity |

3m3/h |

Hydraulic cooler |

Water cooler |

Chassis |

Working pressure |

380V |

|

ChassisModel |

KJ210.6 Track Chassis |

Frequency |

50Hz |

Transmission |

Driving motor + reducer |

Starting method |

Star - triangle |

Steady operating state car mode |

Front leg vehicle stability |

Specifications of cable |

3×35+1×16 |

Vehicle stability assist |

Hydraulic winch |

|

|

Rotational power stations Diesel |

YC2108 |

|

|

Overall Dimension (including an optional auxiliary power station)

Section Sketch

- Drill Rigs and Rock Drills

- Surface DTH Drilling Rig

- Integrated Surface DTH Drilling Rig

- Underground Mining Drill Rigs and Tunneling Jumbo

- KJ210 Underground Mining Drill Rigs and Tunneling Jumbo

- KJ211 Underground Mining Drill Rigs and Tunneling Jumbo

- KJ212 Underground Mining Drill Rigs and Tunneling Jumbo

- KJ311 Underground Mining Drill Rigs and Tunneling Jumbo

- KJ313 Underground Mining Drill Rigs and Tunneling Jumbo

- All Pneumatic Surface DTH Drill Rig

- Semi-Hydraulic Surface DTH Drilling Rig

- Reinforced Semi-hydraulic Surface DTH Drilling Rig

- KL511 Top Hammer Drilling Rig

- Crawler DTH Drilling rigs

- Anchoring Drilling Rig

- KZ5 Cutting Drilling Rig

- DTH Drilling rig

- Rock Drills and Jack Hammer

- Hand-held Rock Drill

- Air-leg Rock Drill

- Pneumatic Rock Drill

- Water Well Drilling Rig

- Geothermal Water Well Crawler Drilling Rig

- Wagon Water Well Drilling rigs

- Core Drilling rigs

- Road Machinery

- Crawler Mucking Loader

- Air Pick

- Auxiliary Equipment